About Our LED

What is your criteria in choosing one LED brand name? Is it about price that you look at? Or do you depend on your suppliers who make the decisions just in accordance with listening to the “rumors” that flow from one factory to another?

We do it in a very different way. In our criteria we have two steps in deciding who our supplier will be.

Step One: Examination and Inspection:

1. The factory must be a well-managed factory. They have clear quality management guidelines and good implementation processes that are strictly under control;

2. The manufacturer of led should have a trackable history, i.e. they should have a good reputation in the market;

3. The CEO of the manufacturer should be a technically knowledgeable person, and it would be better if he used to be an engineer;

4. They are honest people and tell the truth always;

Step Two: Testing by us:

More important than Step One, we do our strictest tests on the leds that we intend to use in our products. The following is an example Test Report translated in English.

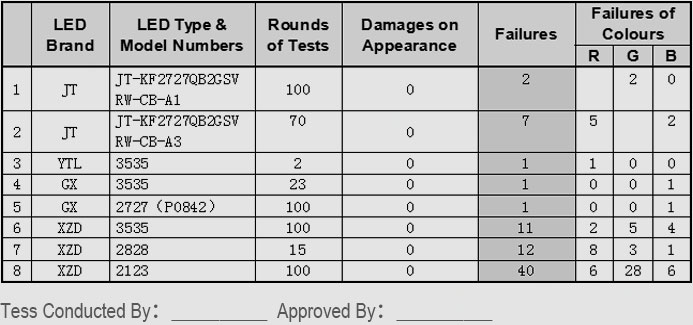

Reliability Testing on Led(SMD Outdoor)

1. Name of Testing: Reliability of Led (SMD Outdoor)

2. Purpose of Testing: To find out reliability level of the outdoor SMD leds in terms of durability under high temperature and water resistance at extreme weathers and the rapid shifting of such extreme weathers;

3. Criteria: A testing method typical in the led packaging industry;

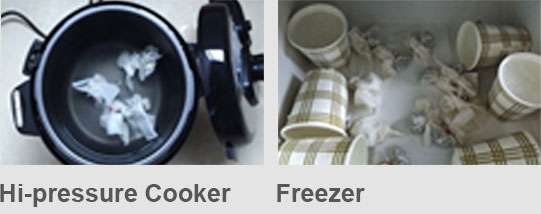

4. Description of testing method: Cook with water in a high-pressure cooker for 30 minutes, then shift the subjects to a freezer for 30 minutes. Such two processes make up for one round of the testing. There are 100 round in each testing program.

5. Testing conditions: 1. Pressure level of the high-pressure cooker is 1.8MPa, and the temperature inside the freezer is -25℃;

6. Judgment Criteria: after 100 rounds of testing (shifting from high-pressure cooker to freezer for 30 minutes respectively for 100 times), we will find out: 1. If there are damages on the appearance of the leds and how many; 2. If there are any failures in leds and the percentage v.s. numbers of such failures by electrifying them piece by piece.

7. Time of Testing: 10th July 2015 to 14th July 2015

8. Pictures of tools:

Different Types of Leds That Darklight Technology Uses

Outdoor SMD:

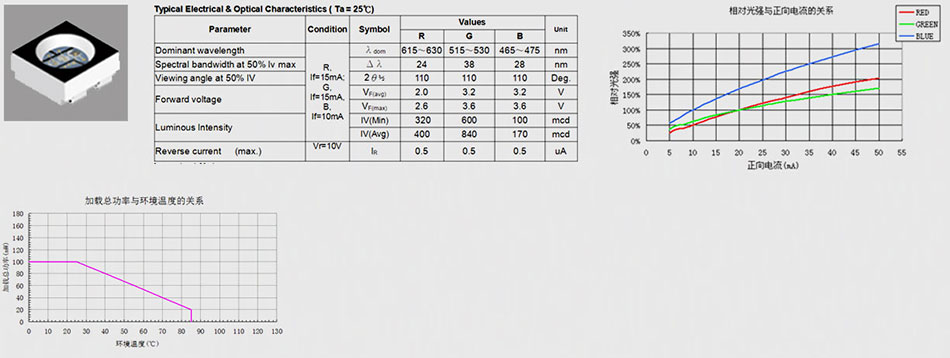

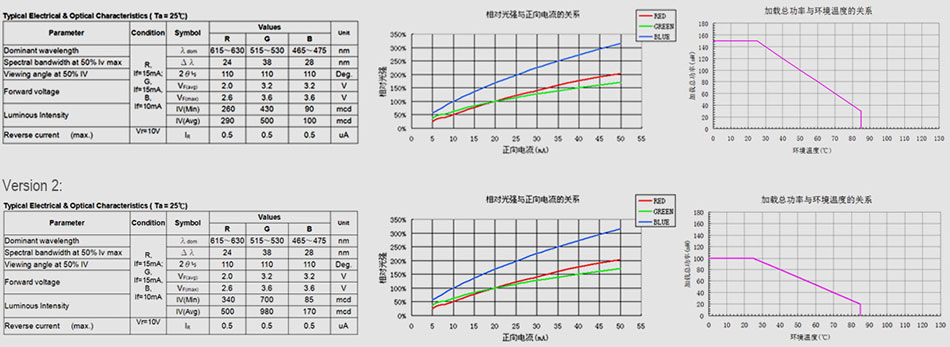

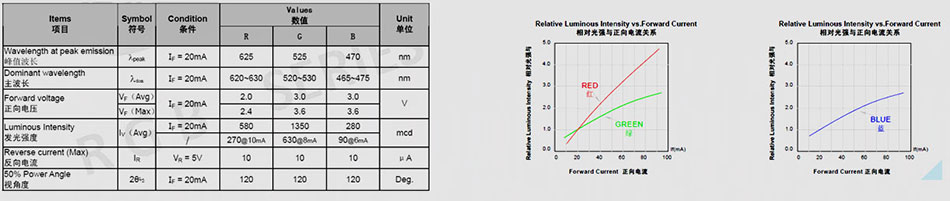

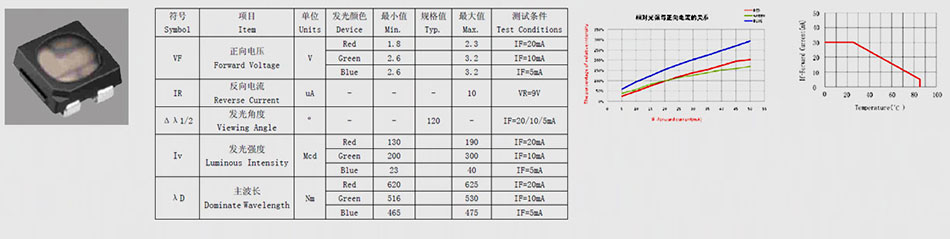

SMD 2123 Outdoor

1. Application: Outdoor, Water-proof;

2. Products Applied in: 3.2mm, 3.9mm, 4.3mm;

3. Version 1: Black-faced, creating superb contrast;

4. Version 2: White-faced, delivering ultra high brightness;

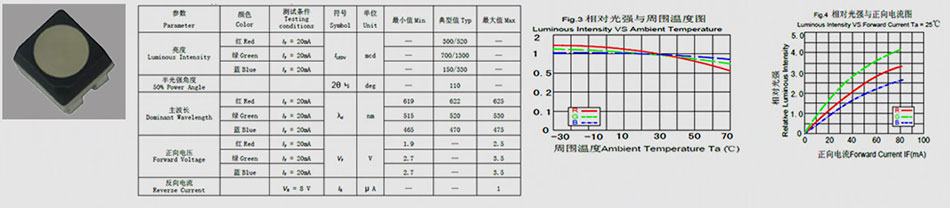

SMD2623 Outdoor

1. Application: Outdoor, Water-proof;

2. Products Applied in: 3.9mm;

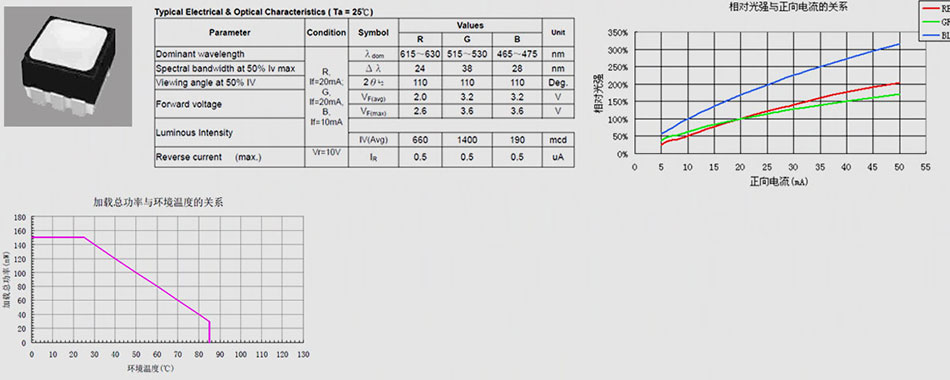

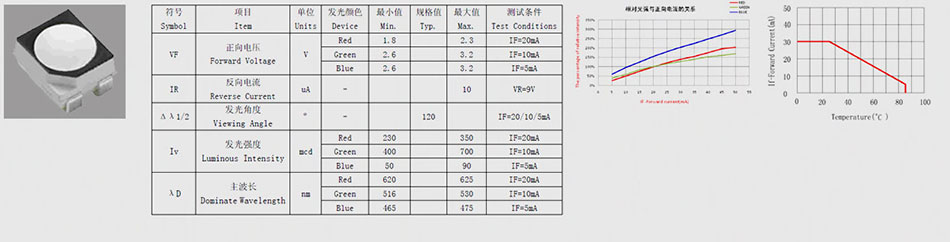

SMD2828 Outdoor

1. Application: Outdoor;

2. Products Applied in: 4.3mm, 4.8mm, 6mm; 8mm;

SMD3535 Outdoor

1. Application: Outdoor;

2. Products Applied in: 6mm, 6.25mm, 8mm, 10mm, 16mm;

Outdoor DIP

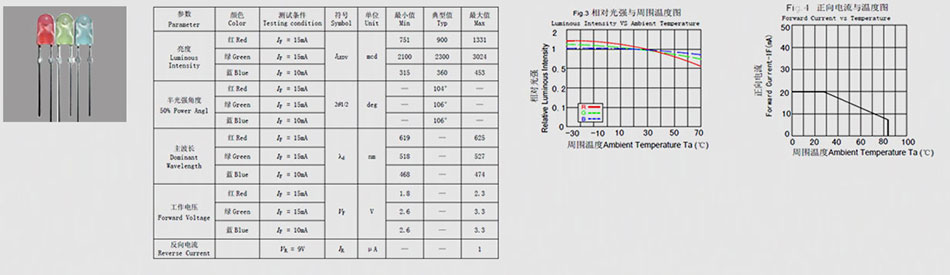

DIP346 Outdoor

1. Application: Outdoor;

2. Products Applied in: 10mm, 12mm, 15mm, 16mm, 20mm, 25mm;

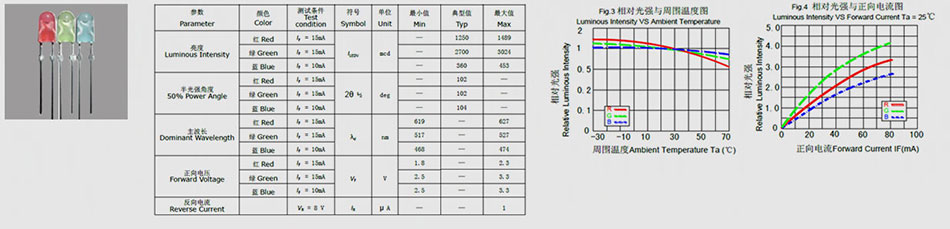

DIP346 Outdoor High Brightness

1. Application: Outdoor;

2. Products Applied in: 10mm, 12mm, 15mm, 16mm, 20mm, 25mm;

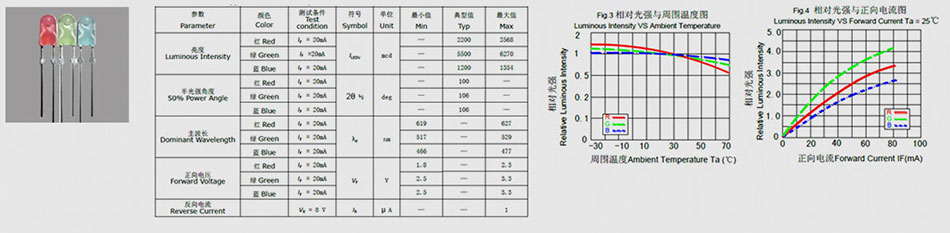

DIP346 Ultra-high Brightness

1. Application: Outdoor;

2. Products Applied in: 10mm, 12mm, 15mm, 16mm, 20mm, 25mm;

Indoor SMD

SMD2121

1. Application: Indoor;

2. Products Applied in: 3mm, 3.9mm, 4mm, 4.8mm, 5mm;

SMD3528

1. Application: Indoor;

2. Products Applied in: 6mm, 8mm, 10mm;

SMD2121 High Brightness

1. Application: Indoor;

2. Products Applied in: 3mm, 4mm, 4.8mm;