![]()

Ever since 2010, when few people in China, or even from Europe really understood what EMC was, Jimmy Feng, one of the partners in Darklight, has started to work on EMC compliance in the LED displays to be delivered to Europe. Having been developing the knowhow to meet this European norm, we are able to have every single product in our product line EMC--approved now. In this field, we are far ahead of our competitors, including the “Big 5”, who from time to time deliver the so—ironically--called “”Chinese CE”, to Europe, in order to get benefits.

What Are Major Differences Between EMC & Non-EMC Products

1.Layers of PCB

At least 4-layer PCB should be used in EMC compliant products. For a “standard” EMC-compliant product this is fundamental. There are certainly different knowhow in the PCB layout than a regular non-EMC PCB as it has a lot to do with sealing and grounding. The cost difference in PCB is also one of the major factors responsible for higher costs for EMC-compliant products. Besides this, it is one of the areas where new comers seeking EMC compliance often make mistakes.

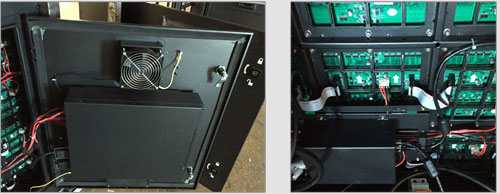

2.Sealing & Shielding

Electro-magnetic emission may leak out from holes, seams, gaps, and non-metallic materials, etc, and cause disturbance, which will lead to failure of compliance. Shielding and sealing is necessary for making a cabinet EMC compliant. You may not need to shield all the cables, and the cost will go up tremendously if you try to shield all the cables, for data and power, and it is not necessary.

How we should do the shielding then?

It is not easy to describe here as it has a lot to do with the knowhow and experiences. The best way, however is to do the basic shielding and add more while testing the unit in the lab. The problem is: How to do the basic shielding? This is what we call the knowhow. There is a simple principle, or guideline, based on which we can tell roughly which cables are to be shielded. That is, the emission does not turn. They go direct at some fixed frequencies. Therefore by measuring the relative length and angles, we can know roughly which points are likely the sources of the emissions.

Sealing: What should we do with the sealing?

The 4-layer PCB in a sense is a kind of sealing, blocking the emission from going beyond the unit from the front. With the same principle, you’ve got to have sealing on the seams, gaps, holes etc. on the doors, at the sides or at the bottoms, where according to the guideline mentioned above, happen to be at the positions where the emissions may reach by measurements.

What materials should we use in sealing the units?

Metallic materials. The best materials to prevent, or let’s use this word: stop, the emission is metallic materials, e.g. PCB (with copper), metallic pastes, metallic tapes, even the shielding material for cables are made with metallic materials.

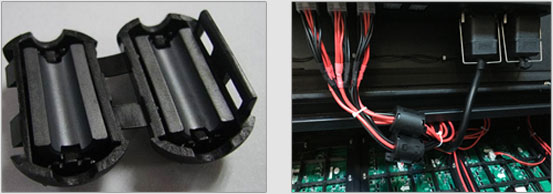

3.Filtering

This may not compose a big part of the costs caused by the fact of EMC compliance, but the filtering of electronic noises are part of the whole scheme in order to make the unit compliant to EMC.

FAQ Regarding EMC Compliance of Led Display Products

1.Will the electro-magnetic emission leak from the cooling fans’ holes?

Yes, and no. You must have the holes(exit of ventilation) designed in the right way in accordance the same principles mentioned above, i.e. you must have a sort of sealing or stoppage in measurement of the wavelength and frequency of the radio emission, so as to block the route of its movements. This is key to stop the leaking of the radio emission from coming out from the seams, gaps, and holes, etc.

2.What is the relationship between CE and EMC?

Before 2014, CE consists of two major parts, EMC and LVD. From 2014 on, they have added RoHS to the CE Norm. Whichever version it is, EMC is supposed to be part of CE. Yet, since CE is a so-called voluntary regulation, i.e. when a company who imports such products, if he declares that this product is CE-conformed, it would be acknowledged by the authorities, though when it is found out that his declaration is not true, he will be responsible for rectifying his “mistakes”. Therefore, EMC had not been taken seriously until 1900s of last century when German government published its requirements specifying the norms of EMC, and making it clear that if the requirements are not met in the electronic products, including led displays, punishment will be implemented on those who are found “guilty”.

This act was acknowledged and copied to their homelands shortly by countries like Austria, Switzerland, Denmark, the Netherlands, the Scandinavian countries, etc. Since then, EMC has been specified to be seemingly a separate concept or norm to follow in supplying electronic products to Europe. Yet, legally, it is still part of CE, and if you have a real CE conformity, you have EMC compliance.

3.How many companies in China can offer real EMC compliance in their products in this industry?

A handful. There are only a limited number of companies in China that are able to supply consistently products with EMC compliance, including the “Big 5”.

4.Is there any other ways of converting a non-EMC to EMC compliance?

Yes. In fact, Darklight Technology has developed a low-cost method of converting a led display to be EMC compliant. The overall additional cost is less than 8%. This is the most economical and effective way of converting a display into EMC compliance.

5.How can we tell if a display is EMC compliant or not?

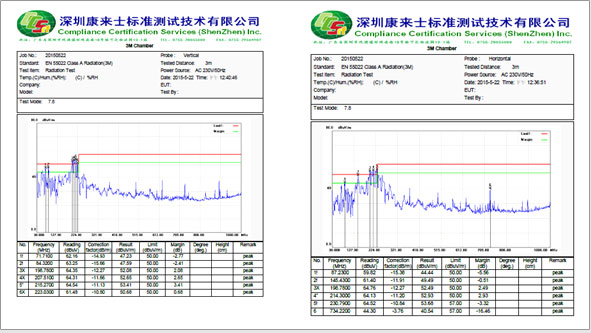

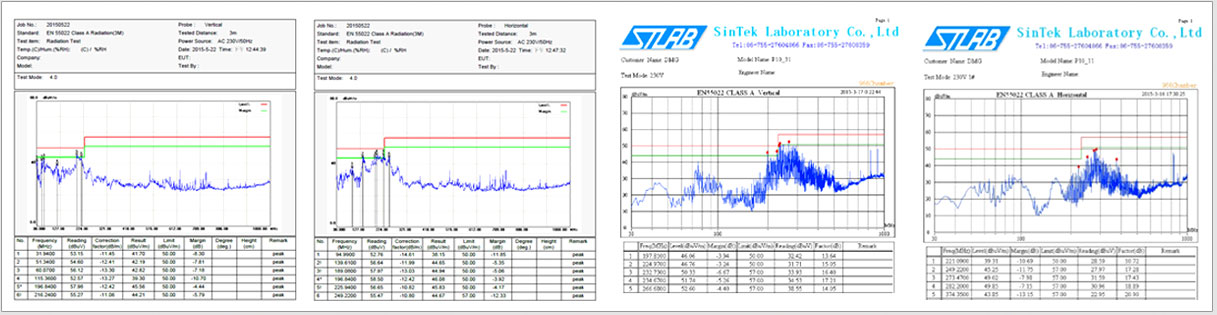

One simple way is to look at the test reports after sending the units to a reputable lab for testing. The following test reports may tell you the difference of compliance and not compliance to EMC:

Compliance to EMC:

Not compliance to EMC: